Scorpion II TL-3 Towable Attenuator Trailer

*Please call us for a Quote on this Item*

The Scorpion II TL-3 Towable Attenuator from TrafFix Devices is the world’s first MASH Tested, Passed, and Eligible Towable Attenuator. The Scorpion II Towable Attenuator attaches to a truck and requires little to no modification of the host vehicle.

Municipalities & Contractors Sign-in for Special Pricing and Tax Rates

CompareDescription

The Scorpion Towable Attenuator requires little or no modification to host vehicle or additional mounting hardware beyond the standard pintle hook and ½” thick × 32″ wide steel frame plate. This single point attachment makes the installation of the Scorpion II TA quick and easy.

When impacted, the Scorpion’s modular design crushes in progressive stages, which reduces the impact forces on the vehicles occupants and results in lower repair costs and easy parts replacement. Rear axle placement improves attenuator stability and prevents the tail from “bottoming out” on driveways and uneven surfaces. The overall length of the Scorpion II TA is only 17′ 10″, the shortest on the market. The integrated electric brake system comes standard on all Scorpion II Towable Attenuators and are automatically activated in the event of attenuator separation or hitch failure. The Scorpion II is equipped with omnivolt LED brake, directional, signal and running lights to further enhance advanced warnings to drivers.

The Scorpion II TA can be used on support vehicles with a minimum curb/actual weight of 12,000 lbs with no upper weight limit (infinite weight). With the Telescoping Anti-Rotational System (TARS™), the Scorpion II TA remained attached to the host vehicle and pintle hook during all impact testing. TARS minimizes the rotation of the Scorpion II during angled and offset impacts and prevents the attenuator from separating from its host vehicle.

The curved side rails of the Scorpion II TA are made from corrosion resistant aluminum tubes and offer full width impact protection along the entire length of the Scorpion II by safely redirecting the impacting vehicle away from the deadly “coffin corners” at the rear of the truck. The Scorpion II Towable Attenuator is the world’s first and only MASH Tested, Passed, and Eligible for TL-3 applications, with and without with optional display panels or message boards; see FHWA Eligibility Letter CC-138 for details.

Specifications

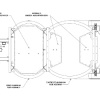

| Length | Width | Height | Weight | Ground Clearance |

|---|---|---|---|---|

| 17′ 10″ (5.4 m) | 8′ (2.4 m) | 3′ (0.9 m) | 1,925 lbs (873 kg) | 12″ ± 1″ (305 mm ± 25 mm) |

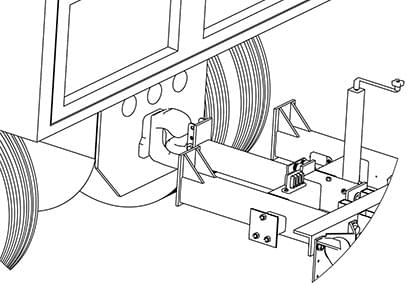

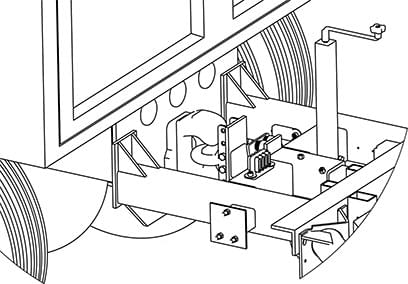

The Scorpion II Towable Attenuator (TA) is a mobile crash cushion designed with a attenuator tongue and axle/wheel that connects directly to the support vehicle’s pintle hook connection and from a lunette ring on the attenuator. The TA can be used on support vehicles with a minimum actual/curb weight of 12,000 lbs with no upper weight limit (infinite weight). The TA has overall dimensions of 17.8 ft (5.4 m) × 8 ft (2.4 m) × 4.3 ft (1.3 m) with ground clearance of 12.0 in ± 1.0 in (305 mm ± 25 mm). The TA consists of three main components: the attenuator tongue, front Strut, and rear Cartridge. The attenuator tongue is positioned nearest to the support vehicle, the Strut is bolted to the tongue and Cartridge. The Cartridge is the rear most component, furthest away from the support vehicle. The attenuator tongue acts as a standard single point connection under normal towing conditions and is designed with an integral Telescoping Anti-Rotation System (TARS) that is activated when the TA is impacted. The forward sliding action occurs during an impact, upon completion of the full telescoping action the outboard anti-rotation supports come into contact with support vehicle frame plate which in turn prevents angular rotation about the rear of the host vehicle. The Strut consists of four outboard convex aluminum tubes forming an aluminum structural weldment. The aluminum structural weldments bolt directly to the TARS tongue and the rear Cartridge. The structural assembly encompasses the aluminum crush Module D. The Cartridge consists of four outboard convex aluminum tubes forming an aluminum structural weldment. The aluminum structural weldments bolt directly the Struts steel angles and rear diaphragm. The TA uses a Cartridge Diaphragm with an axle/wheel attachment for towing the TA. The structural assembly encompasses the two-aluminum crush Module C’s. Attached to the rear most end of the Cartridge is the single crush Module A.

Telescoping Anti-Rotation System (TARS™)

Pre-Impact Condition

Post-Impact Condition